Hydrant Guard Success Story: Walnut Valley Water District, Part 1

Teofilo Pasillas is the Operations Manager at Walnut Valley Water District (WVWD). Before joining the California water world, Teo spent 4 years in the Marine Corps. For him, the waterworks industry is the perfect application for the discipline and ability to perform under pressure that he learned in the Marines.

That’s because chance and opportunity often require Teo and his team to act fast to solve serious problems. After a hydrant shear, WVWD’s operations team has been trained to stay calm and follow protocol to keep things under control. “Otherwise, adrenaline can take over and you may break something, you may unsafely go out in the street and start closing the shutoff valve, and there might be traffic coming and next thing you’re putting yourself in danger.” Because the majority of shears happen at night in high-traffic areas, these protocols are necessary to protect workers from the danger of emergencies in the dark.

But a few years ago, WVWD began questioning if each shear really needed to be such an emergency. They began searching for a solution to minimize complications from broken hydrants. At night, for example, it’s not just about relieving water warriors from after-hours wake-up calls: a midnight shear also requires the assistance of first responders, closing the road with police cars and firetrucks, diverting them away from higher priorities. “One thing we wanted to achieve with Hydrant Guard was to increase safety, both by avoiding shears under power lines and making it so we don’t have to close the whole street and use up municipal resources where they shouldn’t be needed. Now we can do it in a more controlled environment because we don’t have that instant emergency.”

Opting for Hydrant Guard to prevent problems from sheared hydrants was no overnight decision. Each district has their own due diligence process for implementing new devices, and WVWD is no exception. The Materials Committee has a screening process for new products that local residents can be proud of – its thoroughness speaks to how seriously WVWD takes their water stewardship.

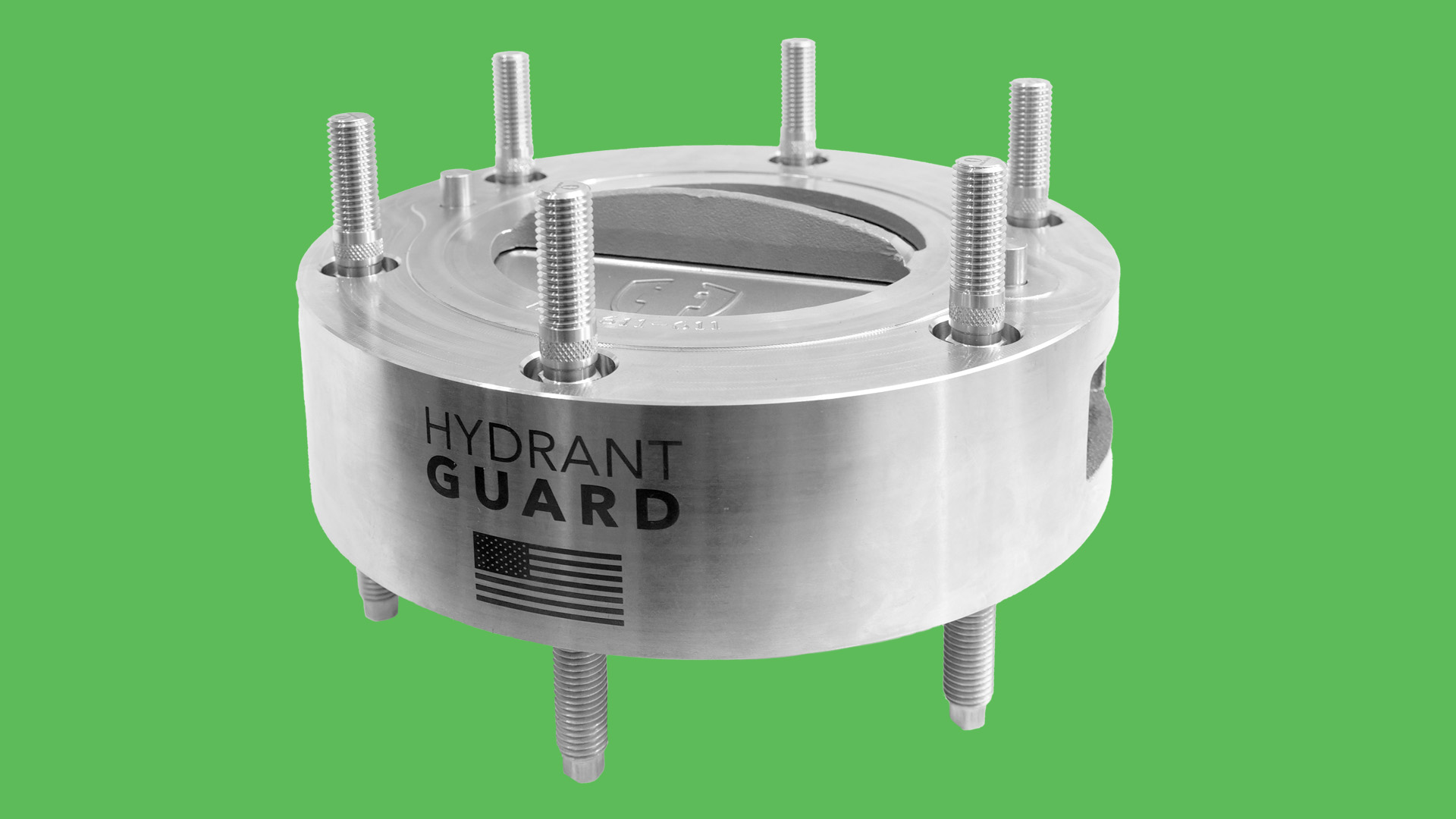

For the WVWD Materials Committee, it was crucial to ensure that any check valve they introduced to their water systems would meet a rigorous set of criteria for health, safety, and compatibility.

Click here to read part 2 of the Walnut Valley story to learn why the Committee selected Hydrant Guard as the valve for the job.